NEW TECH Yard Hydrant

A patent pending device from Improved Devices. Over five years of development and testing in real life situations.

improveddevices.com

making things more useful

Thank you for your interest. We’re always improving our devices from your suggestions and experiences.

If you’re like me you don’t want to have to look all over to find the price for something. The retail price for a single hydrant is $229.00. There are various discounts for the purchase of multiple hydrants. There may be added tax and shipping, depending on your location.

Please consider what you’re getting compared to what you’ve been using. The details are explained below.

The bottom bury section is gray, as a general guide to bury depth. In our standard model moss green is the color on the above-ground section.

Water supply to the hydrant is attached at the 3/4″FNPT connector on the side of the valve housing not under the bottom of the hydrant.

Convenient way to get water to your outside animals and plants year-round.

What’s “NEW TECH” in the NEW TECH Yard Hydrant?

We started from scratch with a new concept about how a hydrant should work. The way the NTYH works is completely different from the traditional pump-handle style hydrants, which have been around about a hundred years with very few changes. This is one case where the old adage “if it ain’t broke don’t fix it” is not applicable. Traditional hydrants have always had problems which have never been resolved.

Those problems stem from a combination of the way they are designed to work and the materials used to make them. Leaks. Corrosion. Stiff handle.

We wanted a hydrant which didn’t have those problems. Now, after five years of development and testing, the NEW TECH Yard Hydrant is a success.

Three major factors are the reason: 1.a completely different kind of valve is used, 2.the materials which are in contact with water do not react with water, and 3.the valve control rod, which is steel and would react with water, is completely isolated from water.

The valve used in the NTYH makes it so there are no rubber or fabric gaskets, “o” rings, or seals anyplace in the hydrant. They’re gone. These are the things which cause the leaks and stiff handle in traditional hydrants.

You can probably guess the practical results in daily use.

Anyone with weak / painful hands can easily turn the hydrant handle “on” and “off”. It’s just a quarter turn side to side. And, over time it doesn’t stiffen.

There’s no leaking around the top gasket, because there is no top gasket. It’s not needed. You don’t have to tighten down a pressure nut until it won’t tighten any more, then finally buy a kit, with more parts than what you need, hoping that replacing the compression gasket does the job.

The valve control rod doesn’t degenerate and eventually fail from frequent or prolonged immersion in water, because it’s never immersed in water. You don’t have to dig up the hydrant and either replace the hydrant or the control rod.

You don’t have to worry about failure of the water delivery tube due to a thinned wall caused by corrosion from prolonged or frequent exposure to water. The water delivery tube is made of material which doesn’t react with water.

You can use the hydrant with or without the brass alloy hose adapter, and with or without the “street elbow” (the 90 degree fitting).

OTHER CONSIDERATIONS:

NEW TECH Yard Hydrant minimizes wasted water when the hydrant is shut off and the water drains out. This is because of the size of the watery delivery/drain-out tubes. It doesn’t take a 1 1/4″ diameter tube to provide plenty of water in most circumstances.

Last but certainly not least is appearance. The NTYH has a clean pleasing appearance appropriate for anyplace, including landscaped areas. If you don’t like the color, feel free to paint it the color you want.

A lesson learned from traditional hydrants:

The brass alloy used in the valve of traditional hydrants is very resistant to degradation from contact with water. So, even though the valve in the NTYH is a completely different configuration, it’s made of a water resistant brass alloy, which has proven to be very reliable.

Water flow control:

The valve in the NTYH is not intended to control the flow of water. It is either on or off. You control water flow by whatever device you attach to the hydrant, like a hose with a nozzle.

The handle provides comfort and ease of use.

We tried many other more “sophisticated” and stylish options for the handle shape but came back to the simplicity of this because of how well it works and how good it feels.

It’s one inch diameter UV protected schedule 40 non-metallic PVC conduit, six inches long.

If you’re concerned that it’s open configuration could make a good place for some pests, like mud dobbers, just fill it with some cheap steel wool or expanding foam. We’ve never had a problem.

DURABILITY & PERFORMANCE

The outside tube of the hydrant is made of tough rigid, UV protected, 2” diameter PVC with 3/16” thick walls. It’ll hold up to just about any type of common use and abuse. BEWARE – Locating ANY hydrant inside a stock pen or where a vehicle can run over it is not good idea.

Different types of rigid and flexible plastic have been selected to do different jobs through out the NEW TECH Yard Hydrant. None of them react or degrade in contact with water, dirt, or just about anything else. It should last a long time under normal use.

The NTYH works well at pressure as low as 20psi. We use 35 to 55psi. 90psi shouldn’t be problem. Any higher psi is very hard on any type of plumbing elements.

BURY DEPTH

Our standard length hydrant is designed for the bottom of the valve housing to be buried between 20 and 30 inches deep. The NEW TECH Yard Hydrant measures 47 ½ inches from the bottom of the valve housing to the water outlet, so you can bury it up to a depth of 30″ and still have room to place a five gallon bucket underneath the water outlet.

If you need something longer for a deeper bury depth, it can be made, but expect an additional charge for design time and added materials. We require you to get a quote first!

For any yard hydrant in a locational with seasonal freezing:

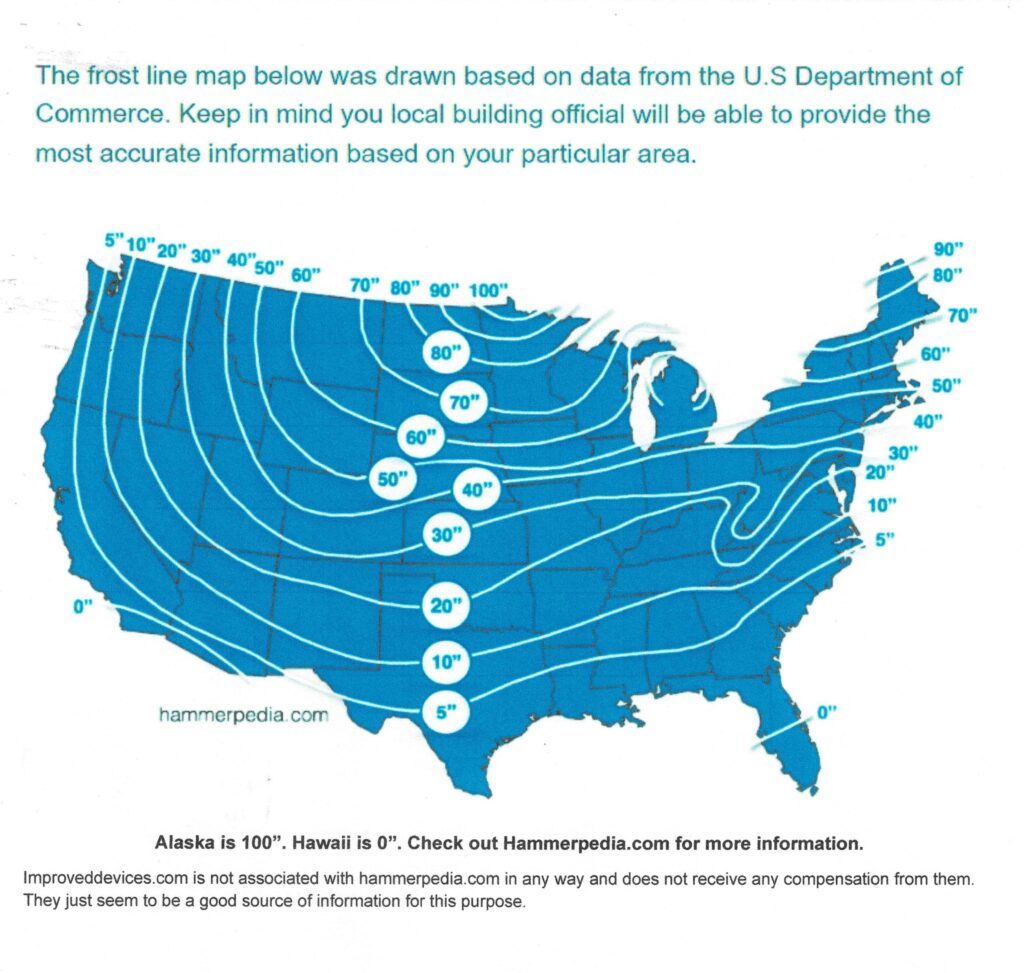

The bottom of the hydrant, where the valve is located, needs to be buried below the frost penetration line. This depth varies depending on the area where you’re using it. See the map below for a general idea.

This map shows general frost penetration depths across the continental USA. For anyone who buys any frost proof yard hydrant check with your local building department to make sure of the specific bury depth you need.

A Note About Stabilizing Your Hydrant:

When you install your yard hydrant keep in mind where you’re going to put it and how you’re going to use it. With frequent use and any rough treatment it’s a good idea to stabilize it, not just put it into the ground free standing.

This is true for any type of frost proof yard hydrant, including the NEW TECH Yard Hydrant. Frequent use without stabilizing it, no matter the type of yard hydrant, is more likely to lead to problems. This is especially true in soil which doesn’t compact well. Some people use cement, but that makes any future changes very difficult. The photo below shows one way of stabilizing a hydrant which works well, although it could be a little cleaner looking.

Detailed installation instructions and suggestions for the NTYH are included with the purchase of the hydrant. Much of it applies to the installation of almost any frost proof yard hydrant.

How did the NEW TECH Yard Hydrant get started?

In short, the final straw was my wife’s hands. They got to the point where she could not raise and lower the handle of the old pump-handle style hydrant because of pain and weakness when she tried. But let’s back up a bit.

It’s exciting to move onto a bare piece of land with just a dream in hand. Then it turns into work. Once you have animals, there’s feeding and watering, and everything else that goes into taking good care of them. There’s the big garden. There’s also a small orchard, if forty-eight fruit trees is all that small for a “small” place.

Everything human, animal, and plant needs water. Water for the house is one thing, and it has it’s own set of challenges. Water for the animals and plants is something else entirely.

To get water where we need it we use frost proof yard hydrants. Like everyone else in our shoes, we purchased and installed the old fashioned ones with the pump-handle style handles, the ones that raise up to open and push down to shut off.

It wasn’t long before the hydrants started to leak around the compression gasket at the top, around the valve control rod. There’s no problem getting water. It’s just a nuisance. For a few times you can tighten down the nut on the compression gasket to stop the leak, or at least slow it down. So everything is fine for a while, but it gets worse with use over time.

The hydrant in our barn gets turned off and on four to six times a day, mostly in the morning. The one for the garden and orchard basically is turned on in the spring and off in the fall, but only has water flowing to irrigate specific places at specific times. The one for the buck pen is turned off and on once a day. The one located half way between the house and the well is used maybe twice a week during the spring and summer. In short, we use our frost proof yard hydrants in a number of places and in different ways throughout the year.

After a while the hydrants which are turned off and on the most and the ones which are turned off and on the least start to have problems, although different types.

The hydrant in the barn stopped working properly on a couple of different occasions and I had to dig it up to fix it. In the process I discovered that the rod connecting the handle at the top to the valve at the bottom was corroded so badly it wouldn’t be long before it failed. The inside of the main pipe was so rusted it probably wouldn’t be long before it also failed. (The repair man at the local hardware store said he commonly found the same things when people brought in their yard hydrants to get fixed.)

The hydrant for the garden and the orchard, after being left off during the fall and winter, was so stiff that my wife had a very difficult time even trying to turn it on. It got to the point where she couldn’t. I had to do that for her.

So, I finally gave up trying to fix the old style hydrants and started looking for a better way to build a yard hydrant. In casual conversation with a neighbor one afternoon he made a comment wondering why smaller water lines didn’t have valves which shut off like larger city water lines. The valve is a simple one which you turn by using a long rod with a device on the end which has notches that insert over protrusions on the valve. You reach down into the hole, where the valve is located, insert the notches on the end of the rod into the valve handle and turn. With that idea the direction for the development of a new type of frost proof yard hydrant began in earnest.

Such a simple idea, right? That was over five years ago and it hasn’t been as simple as it might seem to solve all the problems to make the idea into something simple and reliable which works for a yard hydrant.

After many ideas have been tried and tested using many prototypes there is now a frost proof hydrant which eliminates virtually all the problems of the old style hydrants, and has additional benefits. It’s the NEW TECH Yard Hydrant.

The Prior model of the NEW TECH yard Hydrant installed next to the garlic bed. You can see the stabilizing arm attached to the building.